Pin fastening has been commonplace in commercial construction for over 50 years, however, many people still have a hard time understanding how a pin can fasten to steel as securely as a conventional screw fastener. The keys to the performance of pin technology are the design on the pin and the driving system.

Discover How Aerosmith Fasteners Fasten Steel Securely

Video: How Aerosmith Fasteners Work

Transcript: How Aerosmith Fasteners Work

Pins are made of special grades of steel that are hardened with a unique heat treating process, making them ductile and extremely strong.

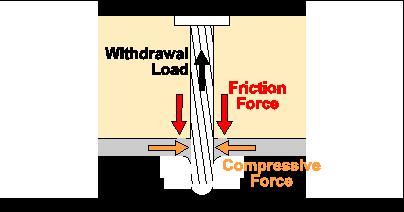

When driven into steel with the proper power-driven tool, their ballistic-shaped point uniformly pierces the steel instead of drilling it out or tearing it like a common nail. The displaced steel rebounds around the pin to create a strong compressive force on the shank of the fastener from the steel.

Each pin and knurling pattern is designed for a specific range of applications, matching unique characteristics and performance capabilities to the material being fastened. When the proper pins are used in the application they were designed for, their holding strength and durability often surpasses that of screws. Organizations such as the Cold-Formed Steel Engineers Institute (CFSEI) and the Steel Framing Alliance (SFA) support the use of pins as a reliable fastening technology. See CFSEI Tech Note 501b